Whether in chemical and petrochemical plants, food production or pulp and paper manufacturing - our reliable A. Hock control valves and actuators can be used in a variety of applications.

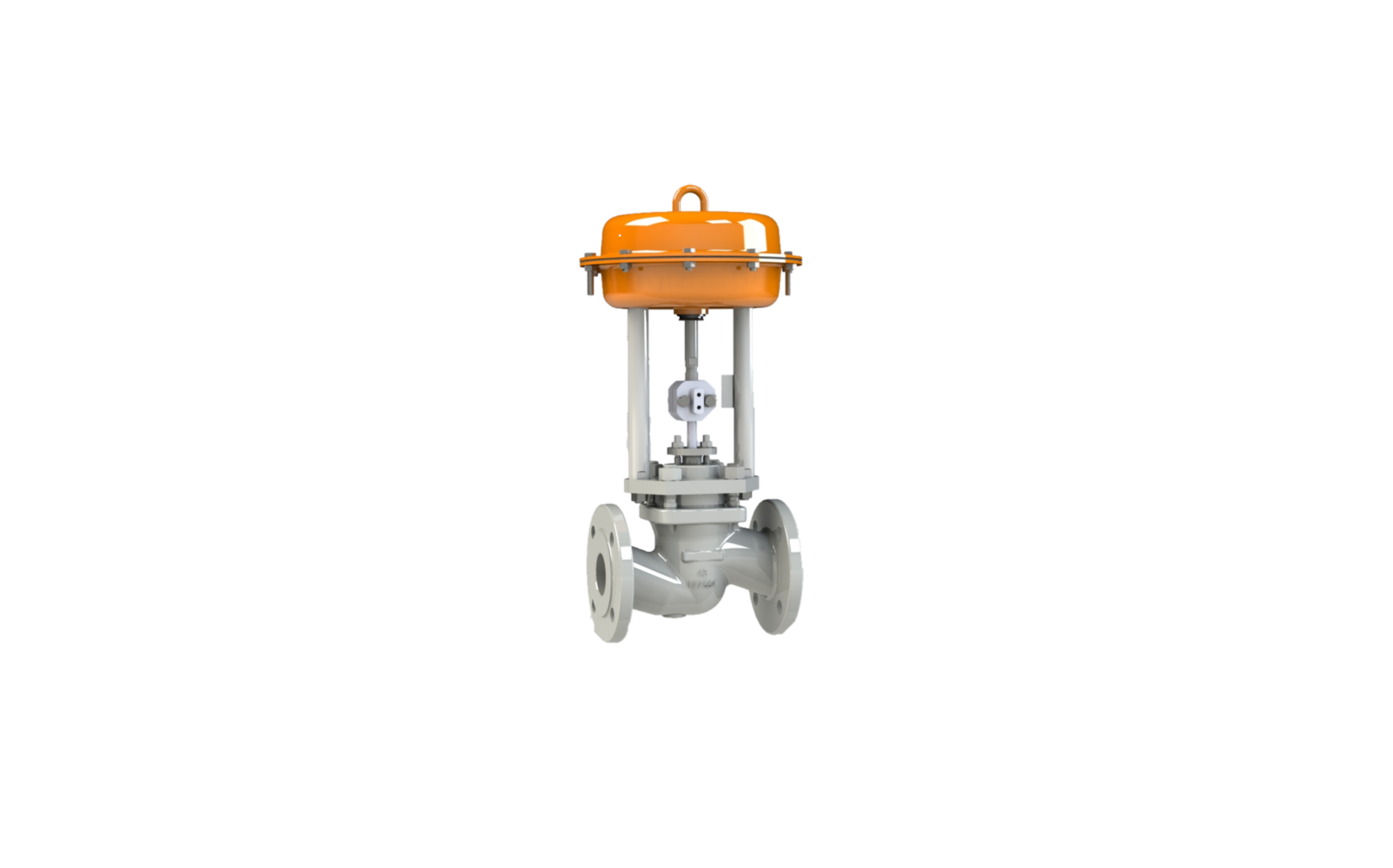

A. Hock's high-quality product portfolio includes flexibly configurable two-way and three-way valves. You decide whether the desired control valve is equipped with a pneumatic or electric actuator.

The A. Hock industrial valves not only support you in maintaining product quality in your plant, they also significantly increase plant efficiency.

Convince yourself!

| Series | Type | Speciality | Pressure Nominal | Diameter Nominal | KVS |

| S2000 | 2-way valve | Allrounder | PN16, PN40 / ANSI150, ANSI300 | DN15 - DN300 | 0,01 - 1600 |

| S2060 | 2-way valve | High pressure single seated | PN63, PN160 / ANSI600, ANSI900 | DN15 - DN100 | 0,01 - 170 |

| S9000 | 2-way valve | Cage guided plug | PN40, PN160 / ANSI600, ANSI900 | DN15 - DN300 | 0,01 - 1400 |

| S2003/13 | 3-way valve | Allrounder | PN16, PN40 / ANSI300 | DN15 - DN300 | 2,5 - 1200 |

| S1003/13 | 3-way valve | HVAC application | PN16, PN25 / ANSI300 | DN15 - DN80 | 2,5 - 100 |

| V5066 | 3-way valve | Thermal oil application | PN16, PN25 | DN15 - DN80 | 2,5 - 100 |

Control valve sizing for all media

The correct valve sizing for a particular application is based on knowledge of

- all relevant process conditions (medium, temperature, pressure, etc.),

- suitable calculation equations (for KV values, noise emissions, cavitation, corrosion, etc.) and

- a weighted evaluation by the project engineer.

With sizing software such as CONVAL and our many years of experience, we are able to specify your control valve to fit exactly.

Learn more about control valve sizing here!

Simple selection of the perfect valve thanks to the modular approach

Challenging applications require the selection of specific control valves. The modular design of the individual series allows us to respond precisely to your requirements.

The selection of a suitable control valve requires special care. It is important to find the best available combination of the following components for your medium and application:

- valve size (Diameter Nominal abbreviated DN)

- pressure rating (Pressure Nominal abbreviated PN or ANSI)

- end connections (flange type)

- valve bonnet (extended bonnet with bellows if necessary)

- valve trim (plug and seat ring)

- suitable materials for body and trim

Documents for the specification of our control valves can be found here!

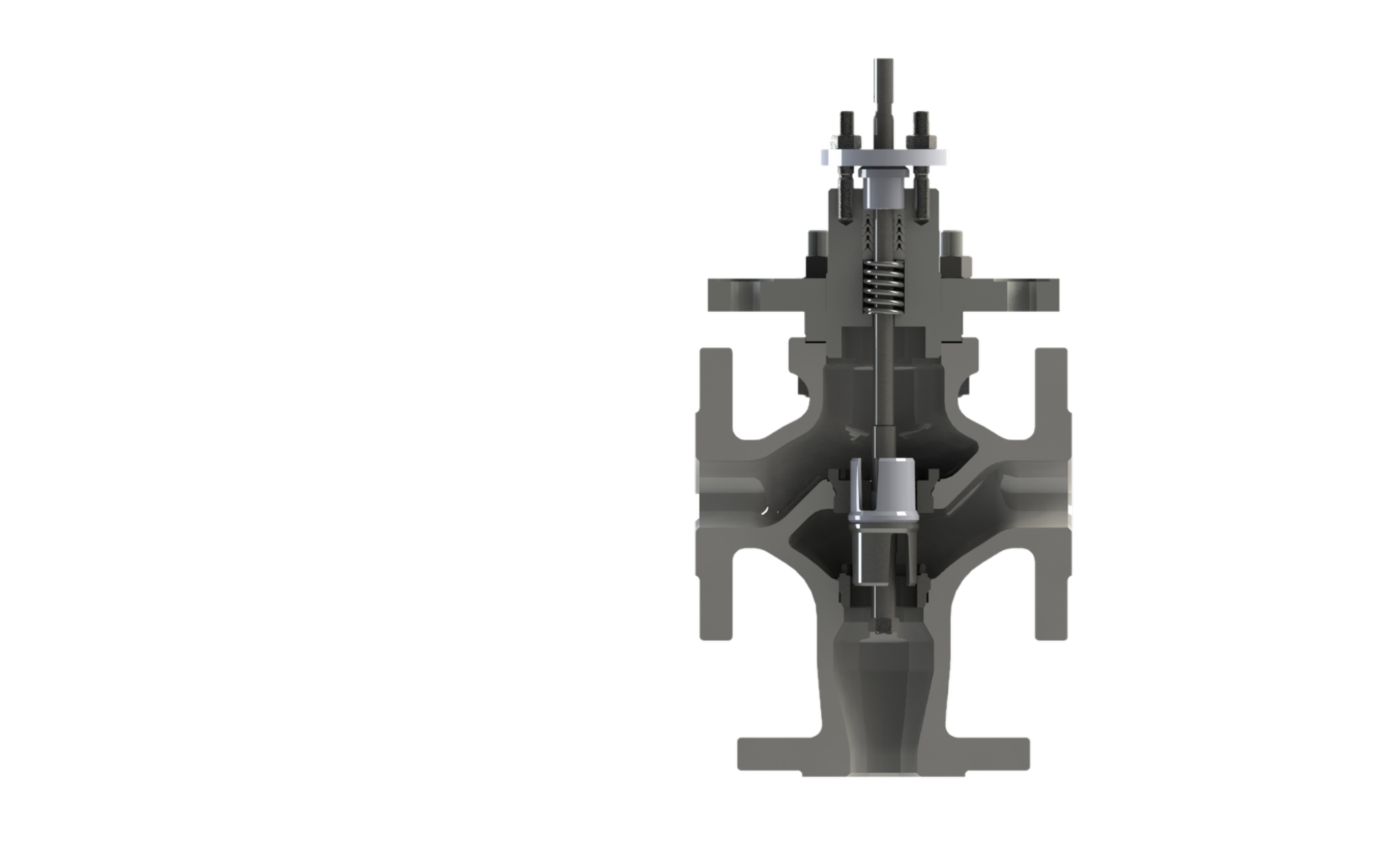

Control valves are designed for reliable continuous throttling of a medium with a minimum of dead band and hysteresis. All valves suitable for throttling a mass flow have one thing in common: they can be considered as a variable restriction, something like a variable resistor in an electrical circuit.

A control valve can be thought of as a device consisting of a body with an interface to the adjacent piping system and an externally powered actuator. Typically, a control valve receives a continuously varying (non-binary) signal (typically 4-20mA) from an automatic control system. The signal can be either electrical or pneumatic.

The valve body is a pressure vessel that must comply with all process conditions in terms of pressure, temperature, corrosion, erosion, etc.. Valve bodies come in many different forms. They differ depending on operating conditions, piping arrangement or other requirements.

Each type or shape of body has advantages and disadvantages and should be selected with care.

The most common function of a control valve is to control a specific flow (e.g. liquids or gases) in a control loop. Another task is to maintain a certain pressure in a system (either inlet or outlet pressure) - despite disturbances in the system. This means that a control valve always has to do with the distribution of energy.

One of the most challenging topics in the specification of a control valve is the definition and selection of the most suitable valve characteristic curve or flow characteristic curve. The most common valve characteristics are the "linear" and the "equal percentage". OPEN/CLOSED applications require a "fast opening" characteristic.

The valve characteristic describes the relationship between the relative valve stroke (h/h100) and the relative flow coefficient (KV/KV100) at constant pressure drop across the control valve.

For more information on the flow coefficient, see the article on the KVS value

There are a number of conditions that must be considered to satisfy not only the process conditions, but also the laws of fluid dynamics.

- Limited Turndown Ratio: A control valve controls the flow of the medium within a certain working/flow rate range. Usually, these limits are between 5% to 95%. Outside this control ratio, the valve characteristic deviates from the desired control response.

- Pressure drop: The valve must have a minimum pressure drop to fulfill its control function (operating range, disturbances, energy conversion).

- Leakage: Control valves are usually not designed for tight shut-off. A minimum leakage rate must therefore be accepted. How high this may be is precisely defined. Shut-off valves, on the other hand, have no leakage or a significantly lower leakage.

Further details about design and functionality of control valves you can find in our knowledge article

Over 100 000 A. Hock control valves in use worldwide

Our valves have been meeting the highest requirements in the process industry since 1954 and are in operation worldwide. Formerly produced by Honeywell Regelsysteme GmbH in Maintal, the control valves have been further developed at the site in Wörth am Main since 2008. But also the assembly, testing and shipping is handled at the company headquarters.

The label "Made in Germany" is particularly important to us. In addition to high quality, among other things due to valve casting in the European Union, we can guarantee short distances and fast delivery times.

How A. Hock GmbH became a control valve manufacturer you can read here!

You want the best sizing and selection of the control valve for your process?

Then feel free to contact us directly!

Technischer Vertrieb

Consult you for projects or inquiries in the area of valve technology or measurement and control

Have 15 years experience with dimensioning of control valves and acutators

Help you modernising your plant